Brands are facing increased pressure from evolving regulations and growing consumer demand for more sustainable packaging solutions.

This is driving significant change across the packaging value chain, as brands seek to replace multi-material, non-recyclable packaging with paper-based alternatives that meet requirements for food contact, shelf life, and recyclability.

To accelerate the pace of innovation, forward-thinking stakeholders recognize that collaboration is essential.

The right water-based coatings can increase the barrier properties of paper substrates and add critical functionality such as heat seal without compromising recyclability.

We’ve worked closely with UPM Specialty Materials for years to engineer paper packaging structures that achieve new levels of performance. These fiber-based constructions have been tested for recyclability according to the PTS-RH 021/97 cat II method and can provide a great starting point for your next sustainable packaging challenge.

This structure features excellent barrier performance against water vapor, mineral oil, grease, and aromas. Target end uses include packaging for coffee, chocolate, snacks, and other dry goods.

Well-suited for the inner liners of corrugated cardboard boxes and pet food bags, this structure resists water and grease, allowing the package to maintain its integrity.

Ideal for frozen foods like ice cream bars, this structure is also heat sealable and can be customized depending on whether you need a stronger moisture vapor barrier or a lower Cobb value.

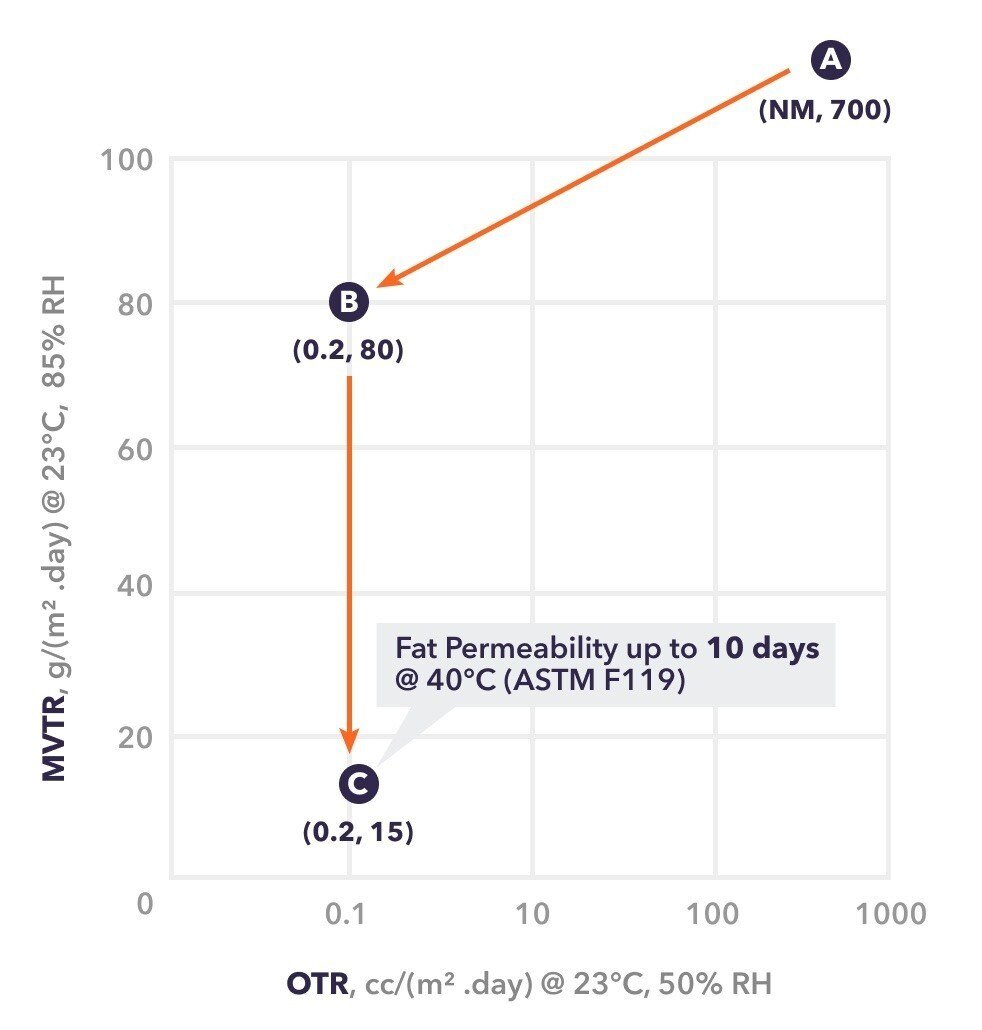

The substrate: UPM Solide™ Lucent 62 gsm

This structure uses UPM Solide™ Lucent paper as the base. With its smooth surface, high density, high strength, and chemical compatibility, it’s engineered to easily accept coatings. (Point A)

The barrier coating: Michem® Flex B1002

Adding Michem® Flex B1002 drastically improves both the moisture vapor transmission rate (MVTR) and the oxygen transmission rate (OTR). In addition to being flexible and overcoatable, this water-based coating also adheres well to porous paper and offers strong oil and grease resistance. (Point B)

The functional coatings: Michem® Flex HS9105 and VaporCoat® 1300

Michem® Flex HS9105 imparts heat sealability at a low seal initiation temperature (90ºC) and generates additional water and oil resistance. VaporCoat® 1300 protects the surface from mars and scratches. Working together, these two coatings further reduce the MVTR. (Point C)

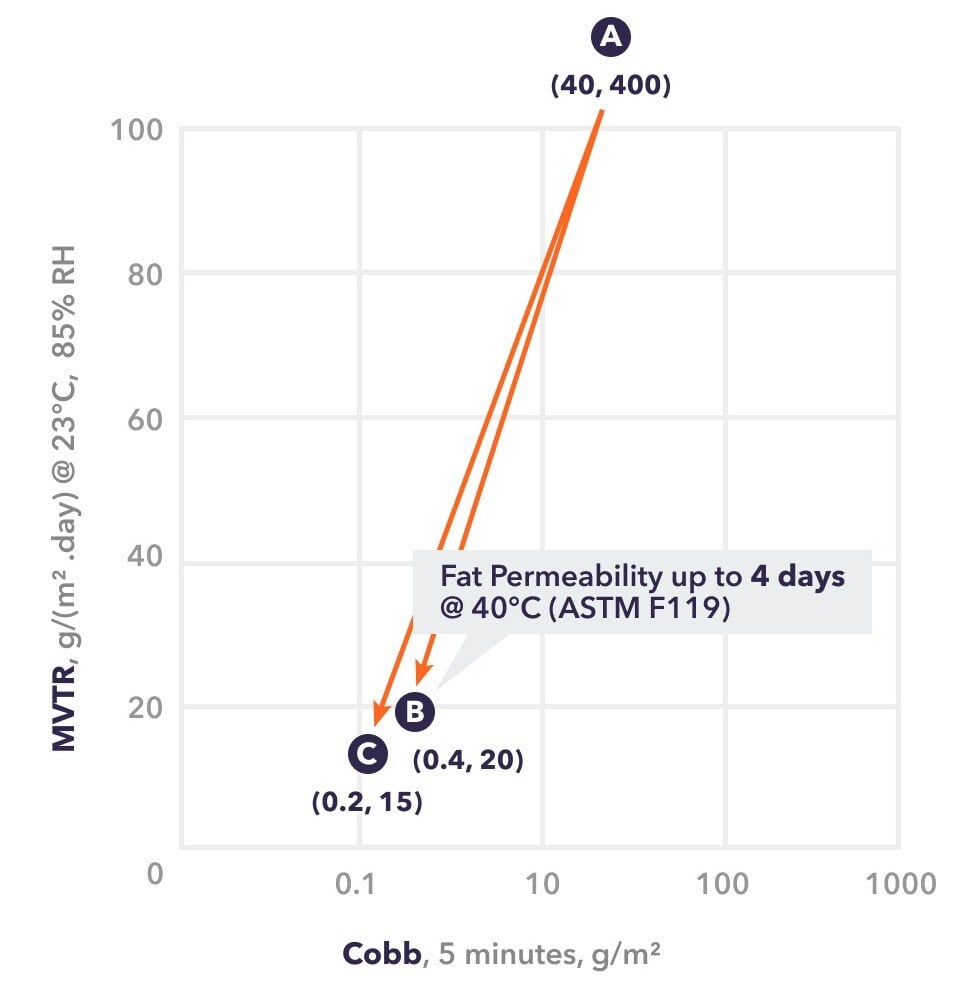

The substrate: UPM Asendo™ 65 gsm or UPM Asendo™ Pro 75 gsm

UPM Asendo™ 65 gsm and UPM Asendo™ Pro 75 gsm are both barrier papers that resist grease and moisture. While both are food contact compliant and recyclable, UPM Asendo™ Pro 75 offers superior print results over other options. (Point A)

The coating: VaporCoat® 2240

VaporCoat® 2240 significantly increases the barrier properties of the paper, improving water resistance, moisture barrier, and grease resistance. Improvements are shown when applied to UPM Asendo™ 65 gsm (Point B), and UPM Asendo™ Pro 75 gsm (Point C).

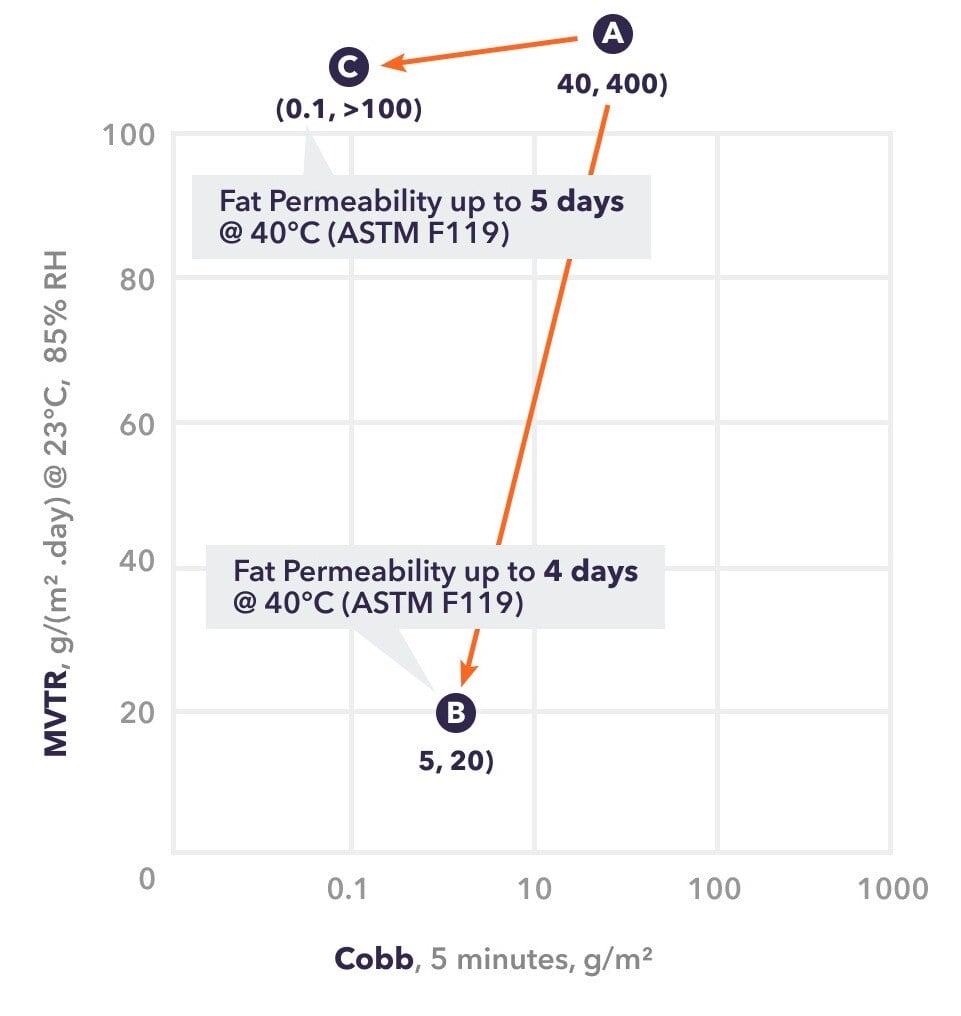

The substrate: UPM Asendo™ 65 gsm or UPM Asendo™ Pro 75 gsm

This structure also takes advantage of the recyclability, barrier properties, and print receptivity of UPM Asendo™ and UPM Asendo™ Pro barrier papers. (Point A)

The coating: 211151PX or 211001PX

211151PX and 211001PX are part of Michelman’s next generation of heat-sealable barrier coatings. Applied at 3 dry gsm, 211151PX provides a more significant reduction in MVTR (Point B), while 211001PX provides a more significant reduction in Cobb value (Point C), with fat permeability up to five days.

To create and support a more circular economy, it’s crucial that forward-thinking leaders across the value chain work together to create more recyclable packaging structures like these.

Raw material suppliers and formulators.

Substrate producers and OEMs.

Converters and brands.

Michelman and UPM Specialty Materials.

Your team and ours.

So, get in touch with our team, tell us about your sustainability goals, and we’ll work with you to design a solution that will work with your performance criteria, your equipment, and your regulatory needs.