Achieve challenging oxygen and moisture barrier performance while maintaining the recyclability of both fiber- and film-based flexible packaging.

The Challenge: Traditional flexible packaging often relies on multi-material structures that are difficult to recycle in order to achieve the required barrier performance.

The Solution: Michelman’s multifunctional coatings impart paper-based and mono-material film structures with critical performance characteristics without compromising recyclability.

Our primers, heat seals, and topcoats work together as a complete coating system to provide enhanced oxygen and moisture barriers at low coat weights while also providing functionality, such as enabling effective metallization and ensuring an airtight seal at low initiation temperatures.

Through years of intense collaboration with BOBST, UPM Specialty Papers, and other value chain partners, we have co-created two groundbreaking structures that combine the right substrates and metallization processes with our coatings to achieve levels of barrier performance never before possible in recyclable packaging. We call these innovative new structures oneBARRIER.

The oneBARRIER solution is commercially available today for both paper and mono-material PE packaging applications.

As demand for paper-based packaging grows, so does the challenge of delivering barrier performance without compromising recyclability. Many fiber solutions fall short, either in protection or in compatibility with recycling streams.

oneBARRIER FibreCycle, co-developed with BOBST and UPM Specialty Papers to meet the performance demands of paper-based packaging, overcomes both, delivering high barrier performance in a recyclable paper-based structure.

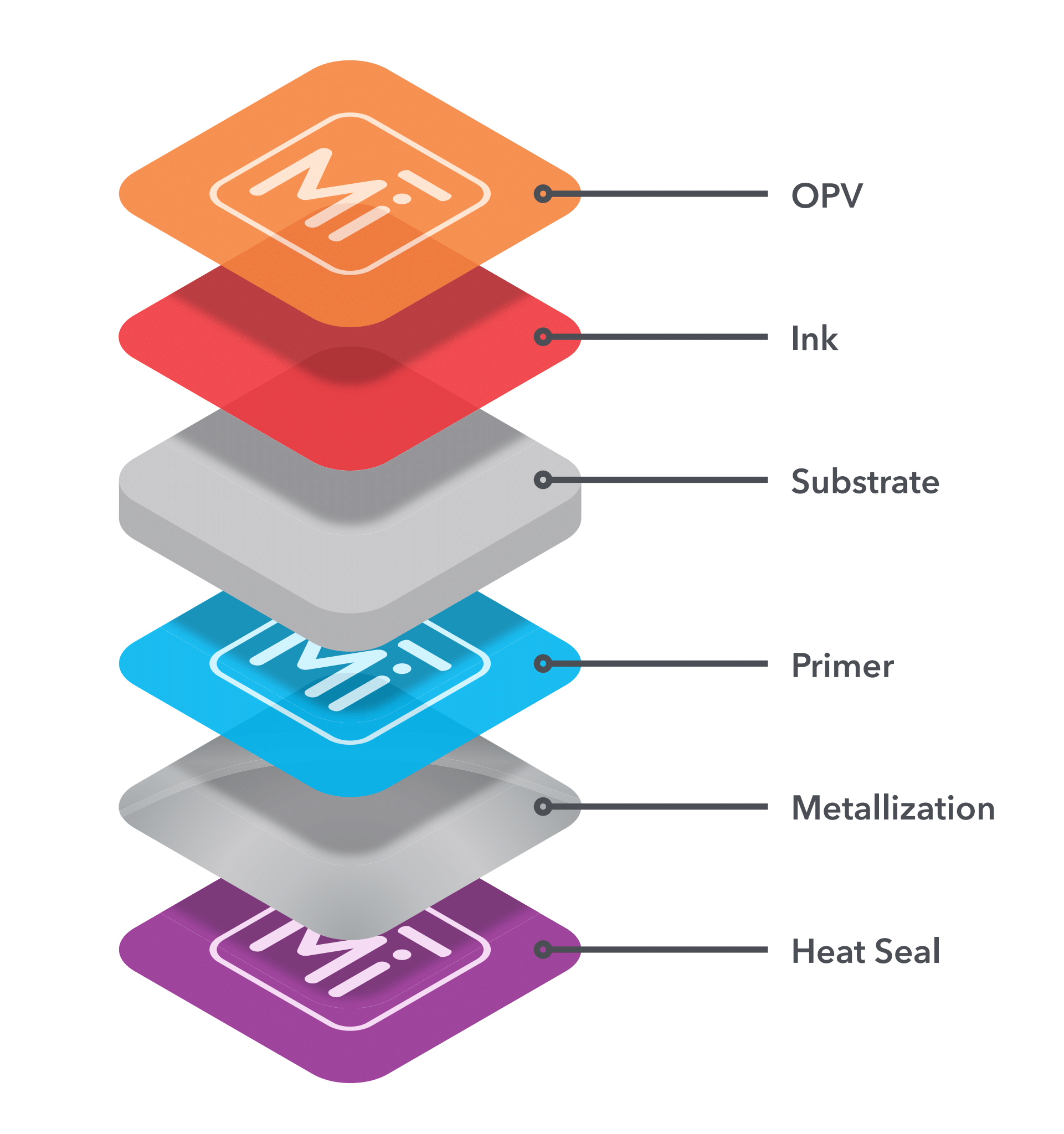

The oneBARRIER FibreCycle structure is constructed by applying a series of functional coatings to a strong, dense, and smooth base paper. Each subsequent layer is added to enhance the properties of the previous one, creating a high-performance, recyclable barrier material suitable for demanding packaging applications.

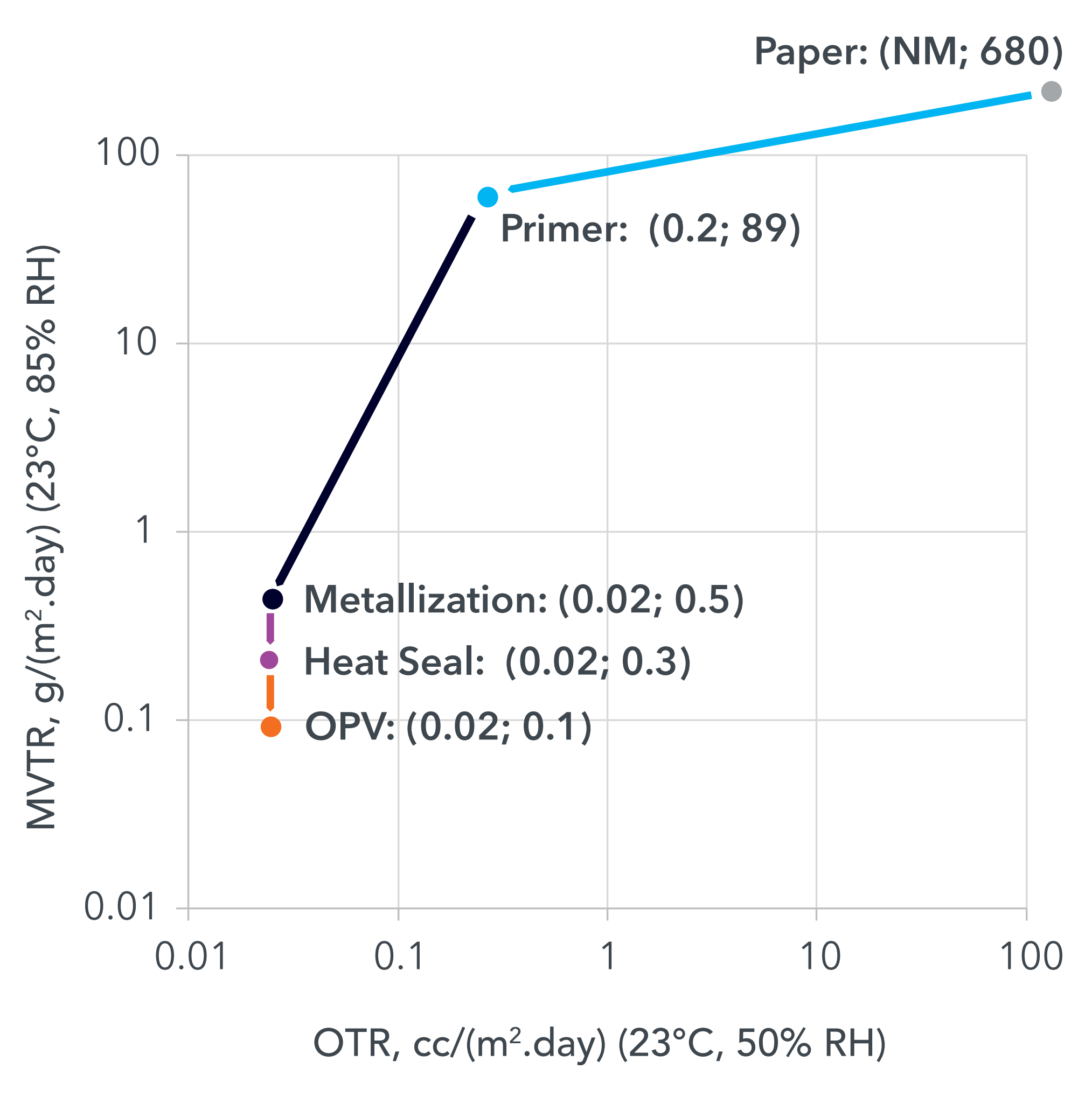

The process begins with a primer, which acts as a foundational layer for metallization. This combination of primer and Alubond® metallization is the workhorse of the structure, providing the most substantial improvements in oxygen and moisture vapor barrier. The heat seal and overprint varnish provide incremental improvements in moisture vapor barrier. These different layers have been designed to work together as a system to deliver impressive performance: an oxygen transmission rate (OTR) as low as 0.02 cc/m²·day and a moisture vapor transmission rate (MVTR) in tropical conditions below 0.3 g/m²·day. These characteristics make the final product a high-barrier, fiber-based packaging solution ideal for protecting sensitive goods.

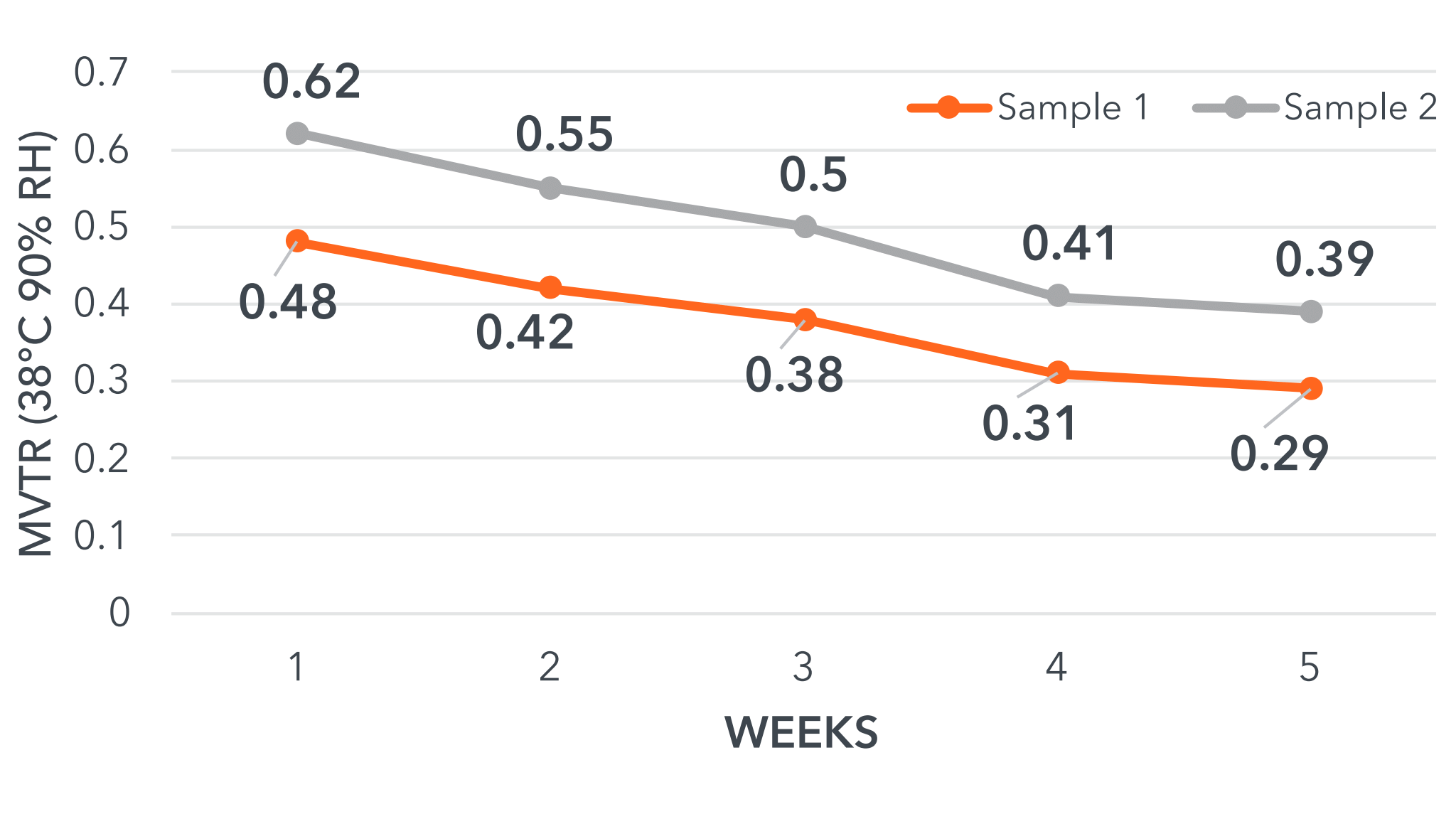

Barrier properties are fully retained after five weeks of aging, even under challenging conditions. In a study conducted at 38°C and 90% relative humidity, the oneBARRIER FibreCycle structure demonstrated consistent barrier performance over time. Moisture vapor transmission rates (MVTR) decreased from 0.48 to 0.29 g/m²·day in Sample 1 and from 0.62 to 0.39 g/m²·day in Sample 2. Barrier integrity is also maintained after conversion into pouches, with tropical MVTR values around 0.4 and oxygen transmission rates (OTR) below 0.1—confirming the durability and effectiveness of the full system.

The oneBARRIER FibreCycle structure has been deemed recyclable according to the following organizations:

It has also won two prestigious awards:

Traditional metallized films offer excellent barrier performance, but they can be difficult or impossible to recycle. For brand owners working to meet sustainability goals, that’s a critical roadblock. oneBARRIER PrimeCycle offers a recyclable, mono-material PE alternative that delivers the same high barrier protection without the tradeoffs.

It was developed in collaboration with BOBST, Dow, Sun Chemical, and Zermatt, and it represents a major step forward in sustainable flexible packaging.

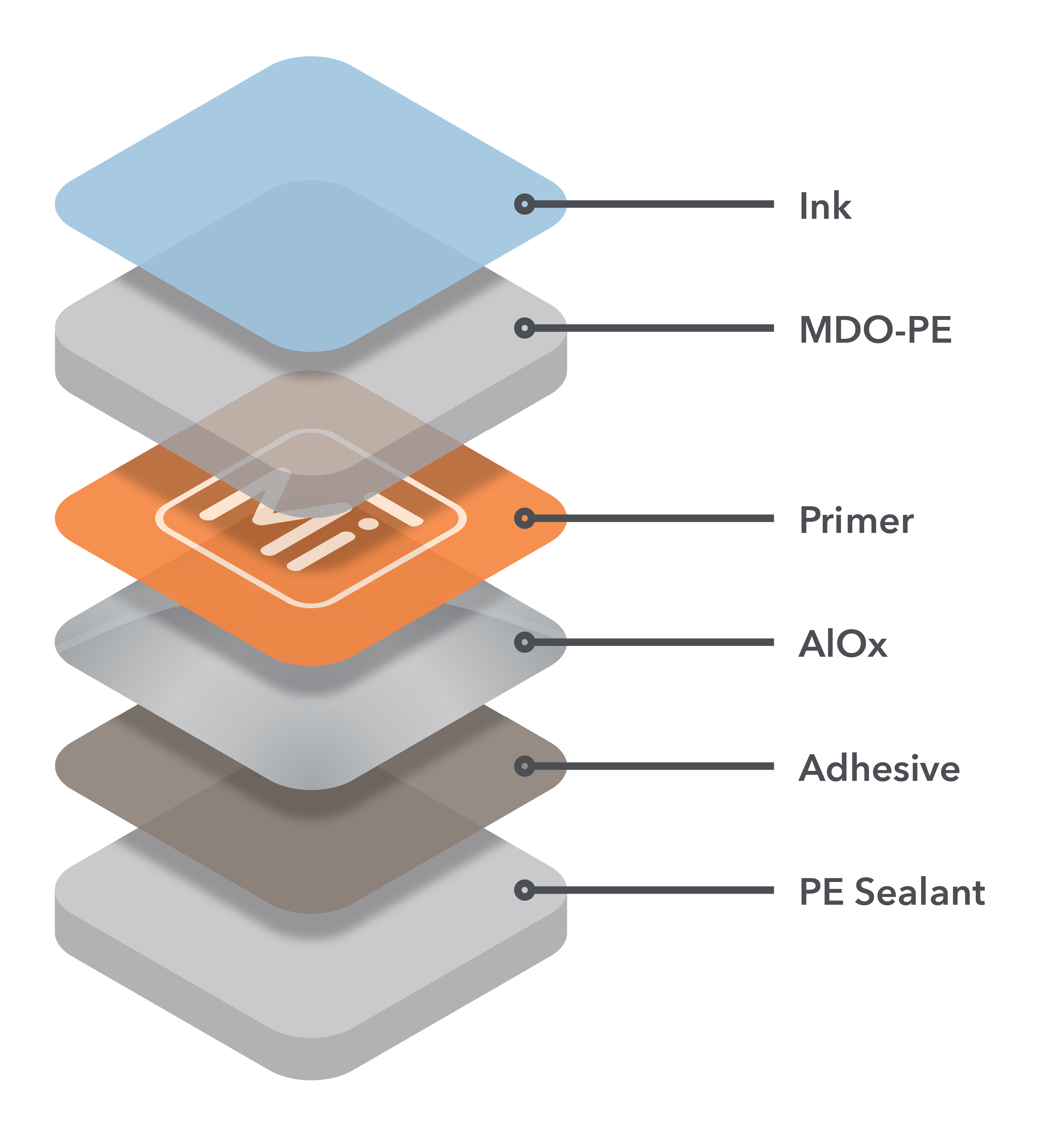

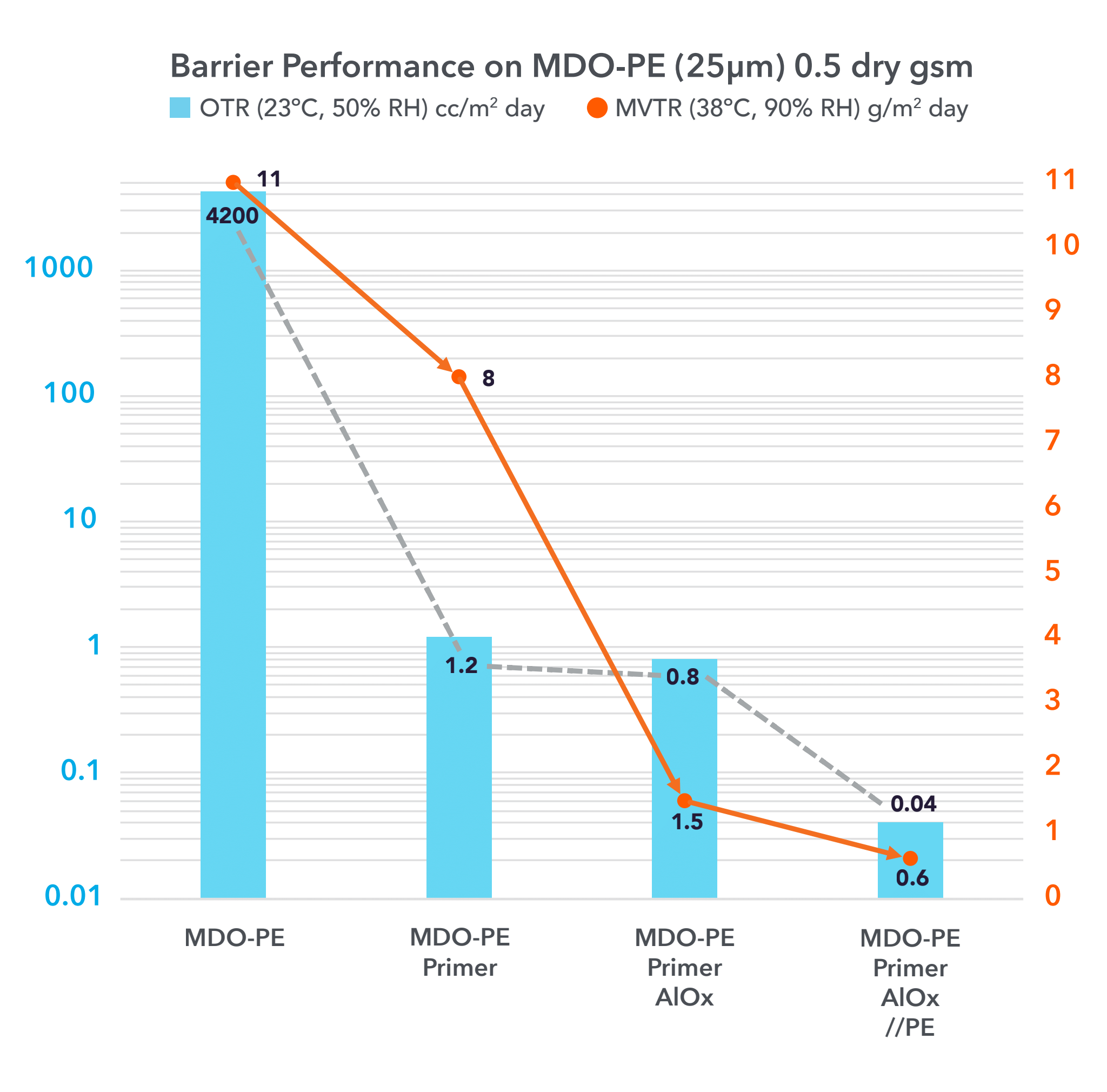

Designed to reduce non-PE components, oneBARRIER PrimeCycle achieves high‑barrier performance levels—such as OTR below 1 cc/m²·day and MVTR below 1 g/m²·day for the transparent AlOx version, and < 0.1 for the opaque version—while maintaining >90% mono‑material PE content. The high oxygen and moisture barrier properties of the packaging structure are maintained consistently during every phase of its lifecycle, from production to consumer use.

A critical component of this system is the primer–Michem® Flex B3530–which provides high barrier performance on the final laminate with a laminate bond strength of >3N/15mm.

oneBARRIER PrimeCycle has been independently certified as Class AAA recyclable—the highest possible rating—by cyclos-HTP, a leading European institute for recyclability and product responsibility. With a 98% recyclability score, PrimeCycle meets the rigorous requirements for polyethylene recycling streams and aligns with CEFLEX D4ACE guidelines. This certification confirms that the structure can be processed through existing recycling infrastructure without compromising material recovery or quality, helping brand owners meet ambitious sustainability targets without sacrificing performance.

Improve sustainability while meeting demanding performance requirements. Contact our team to explore the right coating solution for your packaging application.